Service Hotline:400-0536-010

- Home

-

About

About HENGCHANG

Shandong Hengchang Shengcheng Chemical Co., Ltd. was founded in 1997 and is located in the provincial-level chemical park of Linqu County (No. 2869 Panlongshan Road, Longshan Chemical Industry Park).

-

Product

Product

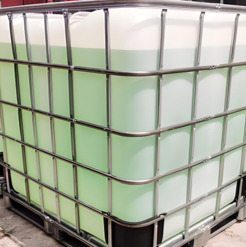

A comprehensive chemical enterprise integrating the research and development, production, sales, logistics, and testing of various types of steel cylinders for liquid ammonia, ammonia water, liquid oxygen, liquid nitrogen, and liquid argon.

-

Technical

Technical

Hengchang is committed to the research and industrial application of technology in the field of hazardous chemical safety production, with a professional R&D team and an R&D center equipped with advanced testing equipment.

-

Service

Service

The total storage capacity of ammonia water can reach 20000 tons, which can ensure stable supply of ammonia water in the face of large fluctuations and unstable supply in the ammonia market;

-

Case

Case

The domestic business of the group mainly includes long-term strategic cooperation with customers such as Huaneng Group, Huadian Group, Datang Group, Guodian Group, Sinopec, PetroChina, Wanda Group, Weiqiao Group, Shanshui Cement, Zhonglian Cement...

-

News

News

The new 150000 ton electronic grade liquefied gas project has a total investment of 160 million yuan, covering an area of 10.98 acres, achieving operating income of 180 million yuan, profit of 90 million yuan, and tax revenue of 39 million yuan.

-

Join Us

Join HENGCHANG

Hengchang Group adheres to the concept of "everyone has talent, everyone becomes successful" and "talent is the foundation of the enterprise".

-

Contact Us

Contact Us

We have a professional technical R&D team and are committed to the technical research and industrial application of hazardous chemical safety production with advanced testing equipment in the R&D center.

中文

中文

400-0536-010

400-0536-010